- Home

- About Us

- Products

- MACHINE

- WELDING ACCESSORIES

- WELDING CONSUMABLES

- WELDING FLUX

- GAS EQUIPMENTS

- SAFETY PRODUCTS

- ABRASIVES

- TOOLS

- Download

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- MACHINE

- WELDING ACCESSORIES

- WELDING CONSUMABLES

- WELDING FLUX

- GAS EQUIPMENTS

- SAFETY PRODUCTS

- ABRASIVES

- TOOLS

- Download

- News

- Contact Us

Product Search

Exit Menu

Products

Products

- MACHINE

- WELDING ACCESSORIES

- WELDING CONSUMABLES

- WELDING FLUX

- GAS EQUIPMENTS

- SAFETY PRODUCTS

- ABRASIVES

- TOOLS

- WELDING TOOLS

- MAGNETIC SQUARE

- INSPECTION MIRROR

- ROD CANNISTER

- CORNER CLAMP

- CYLINDER KEY

- SPARK LIGHTER / FLINT

- TIP CLEANER

- SOAPSTONE HOLDER / SOAPSTONE

- WELDING GAUGE

- MIG PLIERS / MIG NOZZLE REAMER

- CHIPPING HAMMER

- F-CLAMP

- LOCKING PLIERS

- WELDING MACHINE TROLLEY

- INFRA RED DIGITAL THERMOMETER

- CYLINDER RACK

- GAS TESTER

- ELECTRODE OVEN

- HAND TOOLS

- POWER TOOLS

- PNEUMATIC TOOLS

- WELDING TOOLS

CONTACT

- Tel : +86-575-87012323

- Fax : +86-575-87266559

- Email : export@lissam.com

- Address :

Fl. 4th, #5 Qingchuan Building No. 10 Huancheng Road (N) Zhuji, Zhejiang

China 311800

Feedback

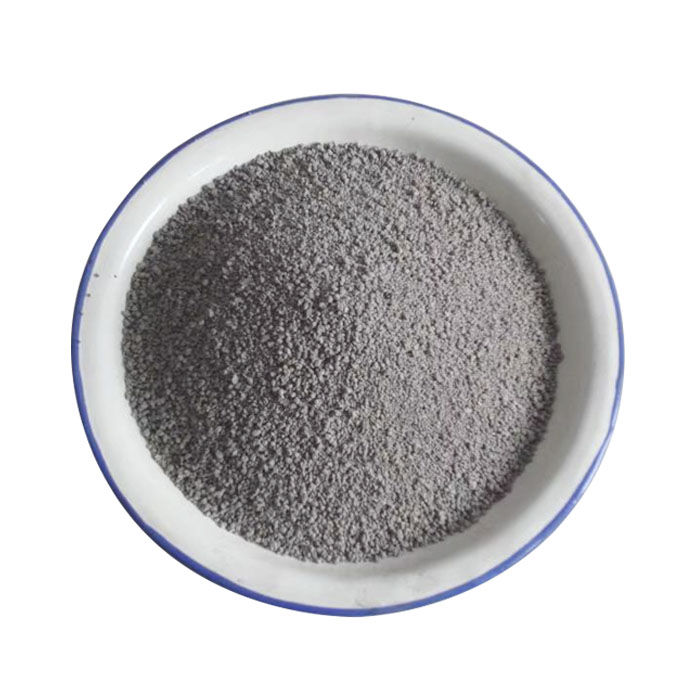

LJ-SJ101

Conforming to: AWS-A5.17 F7A2-EH14 F7A2-EM12K F7A2-EA2-A2 DIN BFB 165AC12MHP5

Description and application

Semi-Basic, agglomeratcd flux for welding of essential steel in combination with appropriate SAW wire(such as EH14, EA2, EM12K etc.). Weld bead hardly increases Si and Mn, it belongs to metallurgy neutral. It has perfect welding performance, stable arc, good surface, excellent slag removal, high impact toughness at low temperature.

The filler metal should be connected to Positive when DC. SJ10 1 can be used for many applications ranging from boilers to pressure vessel, pipeline and low alloy steel structure.

● Flux type: Fluoride-Basic

● Basicity index:1.80

● Grain size:2.0-0.28mm(10-60meshes)

Details

Compositions of fluxes(%)

| SiOe+TiO2 | CaO+MgO | Al2Os+MnO | CaF2 | S | P |

| 15-25 | 25-35 | 20-30 | 15-25 | ≤0.06 | ≤0.06 |

Typical all weld metal mechanical property

| Wire | Yied Stress | Tensile Strength | Elongation | AKV(J) |

| EH14 | ≥400Mpa | 480-660Mpa | ≧22% | ≧27/-40℃ |

Remark

1. Before welding, fluxes should be baked for two hours at300-350℃.

2. Removal of rust, oil, dirt, water, impurities, etc in welding-areas.

-

- feedback

-

-

- Quick Links

- About us

- Products

- News

- Contact us

English

English 淘宝商城

淘宝商城